Standard Semi-tubular Rivets

Features

Semi-tubular Rivets

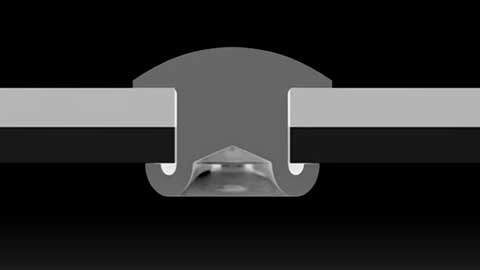

Semi-tubular rivets are set by deforming the hole formed in the end of the shank of the rivet. This can be done using a hand held punch or in high volume applications, fully automatically using a purpose built riveting machine.

- Simple no-special-skills-required fastening

-

Semi-tubular rivets are quick and easy to fasten using a rivet setter and do not require extensive operator training to use.

- Reliable Fastening

-

Semi-tubular rivets do not loosen easily, provide reliable fastening, and allow for easy after-installation visual inspection.

- Improved work efficiency

-

Replacing screws, nuts or bolts with semi-tubular rivets can greatly improve assembly speeds.

- Customizable to specific applications

-

Semi-tubular rivets can be tailor-made from a variety of materials to be used in a wide range of industries from electrical contacts to decorative applications.

Fastening Process

Specification Table

Fastening Catalog Download

60 years' experience of manufacturing rivets : "Fukui Byora's Fastener Series" leads the industry with total fastening technology.