Medical

Manufacturing medical device components with micro-level precision processing technology

We supply various products for pacemakers, syringes, guidewires, endoscopes, orthodontic appliances, artificial legs, dental equipment, and much more.

Medical parts

We use technologies including cold forming, deep drawing, micro machining to deliver state of the art products for the medical industry.

Applications

Endoscopes, Cannulas, Implantable Pulse Generator, Blood Analysis, Robotic Surgery, catheters, dental products, mandrels, needles, probes, Micro Electrical Contacts and more.

Quality management system certified to strict ISO13485 standards for the medical industry

We produce high-precision products of high and stable quality utilizing the in-house production system and high technical capabilities based on ISO13485. Upon request, we can clean, inspect, and package your products in this clean environment before shipment to prevent contamination (by oil or other foreign matter).

Product examples

The following are examples of products that we have successfully mass produced using cold forming technology.

- Minimum wall thicknessl :

0.00159 in (0.04 mm)

- Characteristics : Deep drawn step

- Minimum wall thicknessl :

0.0019 in (0.05 mm)

- Characteristics :

0.0019 in (0.05 mm) wall thickness at tip (medical)

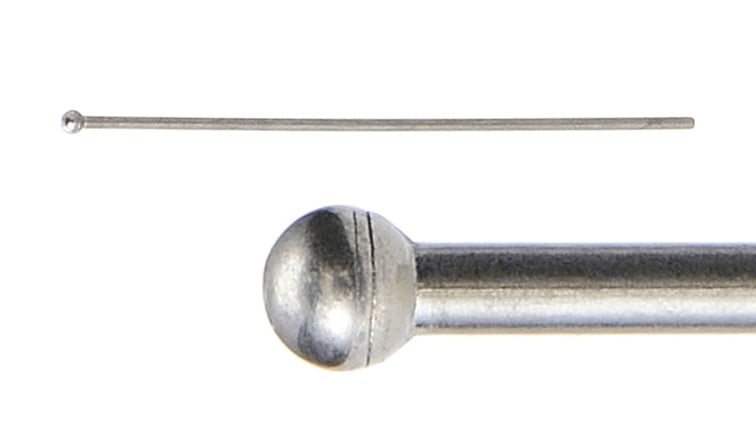

- Characteristics :

Spherical head created using only the heading process

- Characteristics :

Example of a component used in medical equipment

- Characteristics :

Example of a 0.7mm diameter, 35mm long shank with a spherical flange at one end.

- Total length : 420 mm

- Characteristics :

Example of a part combining plastic molding at one end and a sharp point at the other.

- Characteristics :

Example of a hollow part with an irregularly shaped shank.