Deep drawing technology

What is deep drawing ?

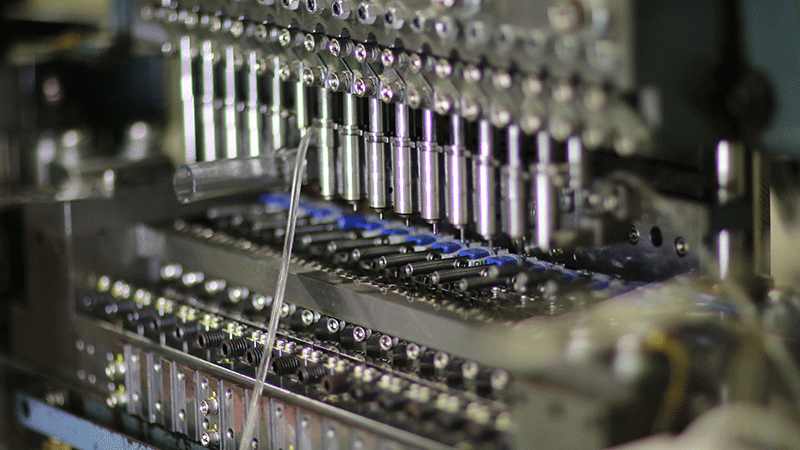

Deep drawing is a forming process in which a thin sheet metal blank is formed by repeatedly applying mechanical pressure with dies and punches. Deep drawing technology enables high-speed production of thin-walled products with deep holes, as well as box-shaped products, which are difficult to manufacture form round wire materials.

Advantages of deep drawing

The deep drawing process has its own unique advantages, some of which include:

Reduction of Raw Material Costs

Compared to machining, deep drawing can reduce material costs because there are less material losses.

Reduction of production lead time

Deep drawing requires less production time than machining or welding, and high levels of productivity can be expected.

Reduction of product weight

Compared to conventional production methods, deep drawing can reduce product weight. This is achieved through work-hardening, by which parts can have a high "strength to thickness" ratio.

Reduction of damage to materials

Compared to machining or welding, deep drawing causes less damage to the material as there is no cutting, grinding, or heat applied.

Our strenghs

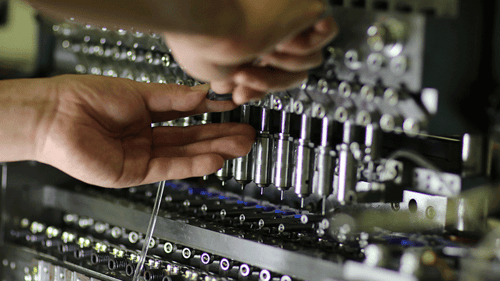

Ultra-thin-walled processing with precision tool manufacturing technology

We specialize in deep drawing micro, thin-walled, and narrow-shaft products using tool manufacturing technology developed over many years producing precision electronic parts with micron-level control. We have experience in deep drawing thin-walled products as thin as 0.0014 in (0.035 mm).

Micro deep drawing technology

Our unique transfer press processing technology, based on in-house development of tooling and production machines, enables us to deep draw "thin and long" products. The minimum outer diameter that can be processed is 0.0118 in (0.3 mm), and deep drawing can be performed up to approximately 20 times the outer diameter.

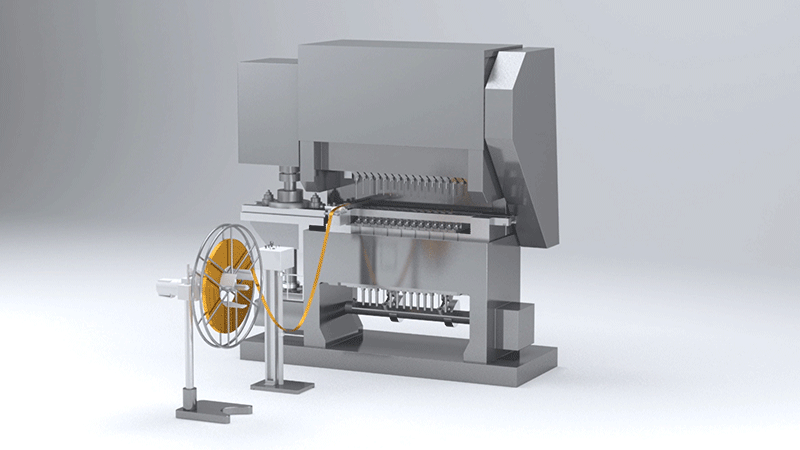

Development of original manufacturing methods made possible by in-house production

We have developed our own original manufacturing methods by in-house production of the tooling and production equipment that are the key to our technology. This enables us to mass-produce products with shapes that cannot be manufactured with commercially available equipment's and tooling.

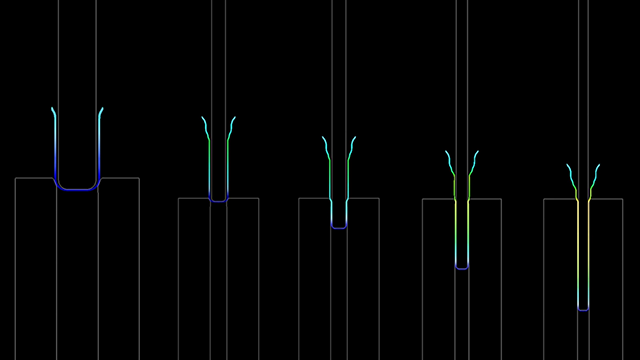

Design simulation for efficient technical proposals

Tool design simulation software enables Byora international to proceed with development in collaboration with the customers from the conceptual stage, allowing us to respond flexibly, such as partial design changes.

Deep drawing capabilities

|

Length

|

Maximum Length |

|---|---|

|

Outer diameter

|

0.0118 in ~0.8661 in |

|

Wall thickness

|

0.0014in~0.0276in |

|

Control precision

|

μin (㎛) |

Materials possible with deep drawing

We have experience in processing the following materials with the deep drawing process. If your preferred material is not listed below, please consult with us.

Product examples of deep drawn products

We have many manufacturing achievements.