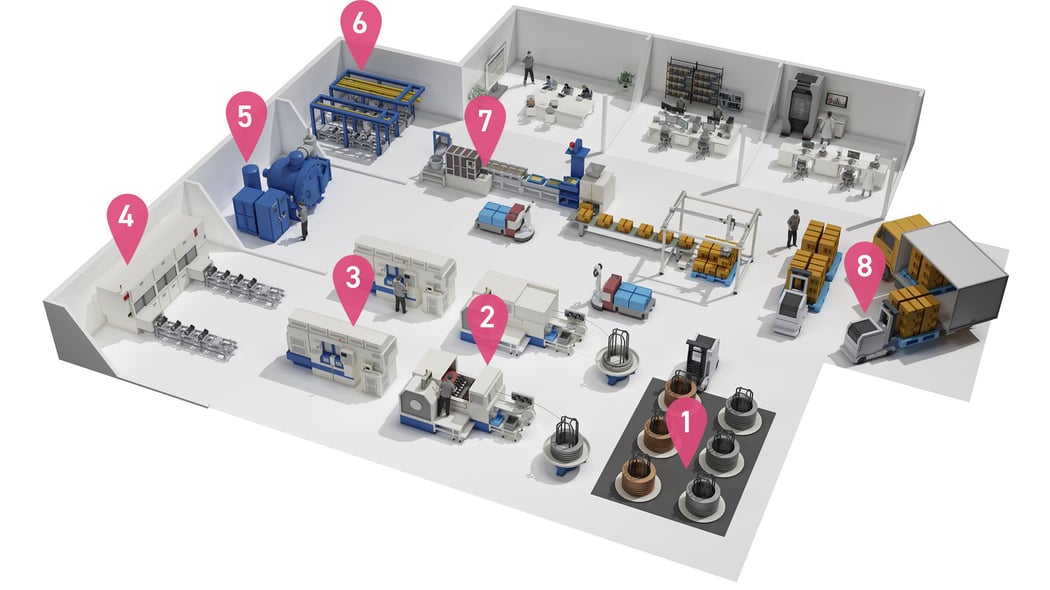

Manufacturing process

Our manufacturing system

The integrated production approach at Byora International's facilities gathers

nearly all steps of a component's production under one roof.

Material

Materials are inspected for defects upon arrival, and can be tracked until final shipment using our centrally controlled in-house production management system.

Primary processing

Cold forming is performed using headers and formers. We have 1,200 formers and headers and produce 12 billion parts per year (8,000 different products).

Secondary processing

We employ a wide range of secondary processes, including machining, bending, pressing, fastening, and plastic molding.

Polishing & Cleaning

Cleaning is often done after heading and secondary fabrication to remove machine oil used during those processes.

Heat treatment

With our vacuum furnaces and other heat treatment equipment, we ensure high quality heat treatment.

Metal plating

Our dedicated plating subsidiary allows us to provide suggestions and resolve technical problems quickly and reliably.

Inspection

We are committed to improving the accuracy of product inspection by checking the dimensions and appearance of products using image-based pass/fail evaluation systems.

Delivery

We deliver products according to your desired delivery schedule.