Secondary processing

What is secondary process ?

Secondary processing allows for more complex shapes when combined with cold forming as the primary process.

Types of secondary processes

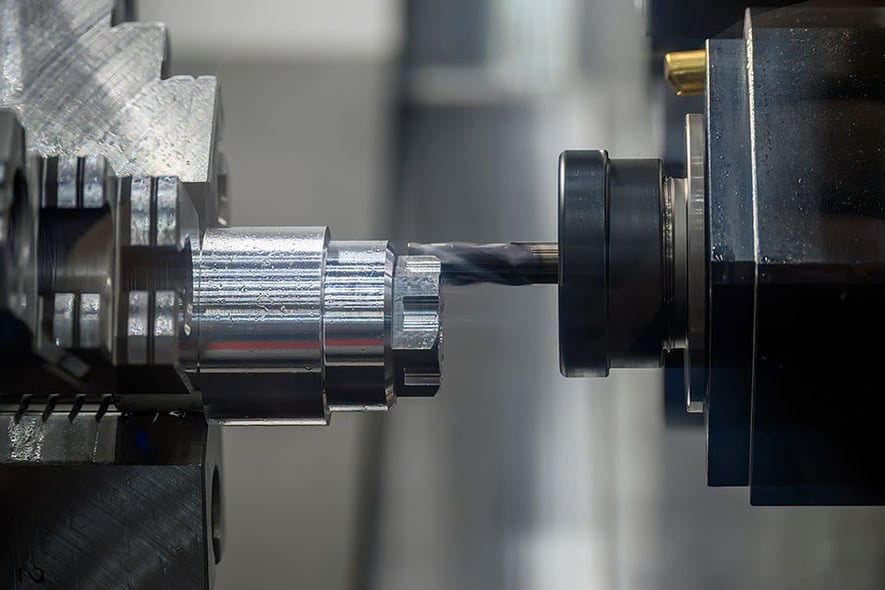

1. Machining, Grinding

Combined with cold forming, machining enables us to achieve a high-precision finish. Compared to a full cutting process, it results in less material scrap, greater cost savings and shorter delivery times.

2. Flattening

This is a process which forms dents or protrusions by applying pressure to a metal material with a die.The flattening process can form various shapes such as cross-shapes and flat shapes as needed to suit part application and requirements.

3. Bending

This process bends metal materials to desired angles using a punch and die. One single machine can handle complex 3D bending.

4. Trimming

This process cut off unnecessary sections after processing with processes such as cold forming.

5. Assembling

This refers to composite processing technology that combines components made of different materials. These include fastening, press-fitting and resin molding.

6. Tapping

This is the process of making a female thread using cold forming. Tapping can be conducted with either machining or rolling, however, we use roll taps which do not generate metal scrap.

Product examples of secondary processing

We have many manufacturing achievements.